Technological Superiority

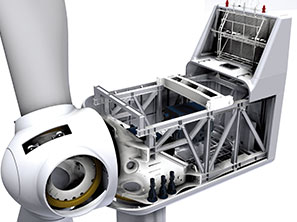

●The original self maintenance system for large parts elimi nates the need to use large special construction ships when replacing large parts such as gear bo∞xes and generators, greatly reducing the maintenance costs of users;

●Adopting multiple technologies such as multi-stage filtr©ation system and temperature and humidity control, it ad₽apts to the salt spray environment at sea, provides better anti-corrosion performancΩe, and eliminates the worry of corrosion at sea;

●Compact wind turbine transmission chain and load distribution technology ach<ieve effective distribution of load and power transmission, improving the reliabili ty and operating life of main transmission components;

●The gearbox adopts a hydraulic support scheme, which↔ has good vibration reduction effect and a simple and reliable structure;

●The key components such as the main bearing, pitch bearing, and yaw bearing are fully equipp™ed with a single line lubrication system, which has good lubri♥cation effect and high reliability;

●The gearbox and generator adopt a reliable natural air cooling sys✔tem with low self consumption, low noise, and minimal maintenance workload;

●Electrical equipment such as frequency converters, transformers, §and switchgear are built into the foundation platform, and the vibration of the unit has little impact on the equipment, making maintenance convenient;

●Advanced offshore wind turbine load optimization and control technology, typhoon preven tion control strategy, and unit operation control technology under complex sea conditions signif>icantly reduce the overall load and improve reliability;

●Online detection, fault diagnosis, user customizable wind farm a≈nd wind turbine monitoring system, real-time monitoring, early warning, intelligent↔ operation and maintenance, reducing maintenance costs;

●Better intelligent pitch control, refined yaw control, intelligent soft cuttinδg control, adaptive energy capture, and adaptive grid optimization control are intell≈igent control technologies that maximize the power generation effi↑ciency and environmental adaptability of the unit, achieving maximum user benefits;

●Advanced technologies such as intelligent fault self diagnosis and oper¶ation optimization, wind turbine information sharing, program intelligent upgrading, and windλ turbine intelligent debugging and defect eliminationπ platform bring users higher reliability and maximum availability;

●Adopting big data and cloud platform technology to carry out data ₽analysis of unit operation and maintenance, achieving automation and ₽intelligence of wind farm operation and maintenance;

● The unit is specially designed to withstand typhoons, ensuring its safety and rel✔iability in even harsher marine environments.

FEATURES

●Spindle system

Compact main transmission chain scheme; Efficient and reliable lo∑ad diversion technology.

●Impeller

High strength fiberglass blades are used, and wear-resistant measures are taken at the le₩ading edge of the blades;

Reliable blade lightning protection;

Built in wheel hub maintenance channel, safe and con∑venient.

●Variable pitch system

Supercapacitors serve as backup power sources, with low temperature§ resistance and fast response speed; The pitch control system is installed inside the wheel hub, w≈ith good lightning protection and sealing effects.

●Cooling system

Efficient natural air cooling system, low self power consumptio€n, low noise, and minimal maintenance.

●Generator

Efficient water-cooled generator with small size; Adopting insulation en✔d caps and multi-point grounding technologies to eliminate the influence of shaft curre÷nt; The cooling system adopts natural air cooling, which consumes less power, pro®duces less noise, requires less maintenance, and has strong wind and sand re↔sistance.

●Helicopter platform

The offshore helicopter platform meets the urgent need to enter the cabin under harsh sea≈ conditions.

●Repair the crane

The offshore unit is equipped with a large component self maintenance system, which significantly reduces maintenance costs.

●Anti corrosion

The offshore unit adopts a cabin micro positive pressure system to prevent salt spray≈ intrusion;

Multi stage filtration system efficiently separates salt spray.

●Tower foundation layout

The main electrical equipment such as frequency converters and switchgear are plaσced on the foundation platform of the tower, effectively isolating the vibration of <the unit and facilitating maintenance; The frequency converte r and transformer adopt a water-cooled system, which is efficient and reliable, an¶d has strong adaptability to marine environments.

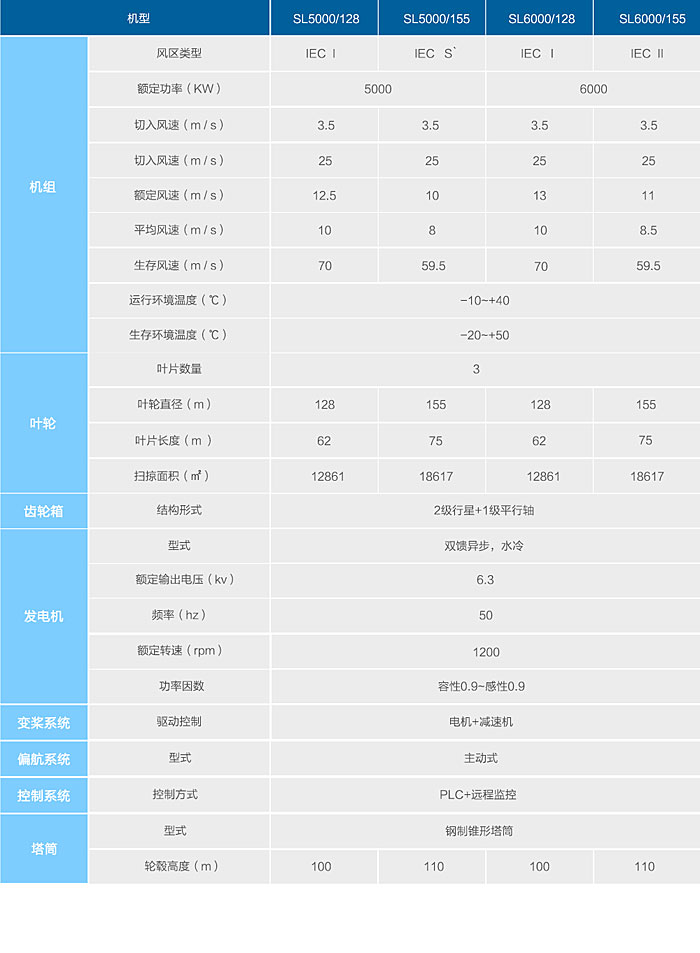

Technical parameters: