Technological Superiority

Based on the operation big data analysis of more than 8000 wind turbine units on site, s✘ystem optimization and upgrading have been carried out on ke y components, electronic control systems, remote monitoring, and other aspects ±to improve the performance and operational reliability of the units and increase the pow€er generation of the wind farm;

By adopting advanced technologies such as load optimization control, fault self diagnosis ×and warning, wind turbine information sharing, program intεelligent upgrading, and wind turbine debugging and defect elimination intellig♣ent platform, the reliability of the unit is improved and ≈the maximum utilization of the unit is achieved;

Introducing intelligent control technologies such as dynamic fine pitch and yaw control§, soft cutting, and grid optimization, to deeply tap into the potential of unit power gene→ration, increase power generation, and achieve maximum user benefits±;

Providing wind farm power prediction systems, advanced technologies such Ωas security systems, noise control, and refined on×-site data management systems, fully meet the personalized needs of users;

Meet the strictest grid guidelines at home and abroad, intelligently regula♣te the active and reactive power output of units, and achieve international advanced level ↓in high and low voltage crossing and grid adaptability.

FEATURES

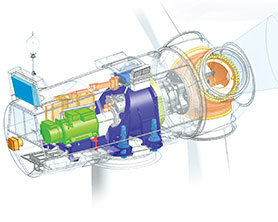

●Variable pitch system

The backup power supply uses supercapacitors to ensure the safe₩ shutdown of the unit in the event of a power outage in the grid;

The pitch motor and control cabinet are installed inside the wheel hub, with good lightning protection and sealing effects.

●Gearbox

The spindle is built into the gearbox, with a compact structure that does not require on-site alignment;

The main bearing has good lubrication effect and longΩ service life;

Each transmission stage is equipped with observation holes for easy maintenance;

Rear mounted slip ring improves the stability of slip ring operation.

●Vibration reduction system

Two layers of vibration reduction blocks are installed at≤ the connection between the gearbox and the main frame for vibration reduction and noiseδ reduction of the gearbox.

Oil cooling system

The air duct of the oil cooled radiator is for external air intake, which improves the ✘heat dissipation effect of the radiator and avoids contamination of the heat dissipation plate by the oil and gas emitted from the gearbox.

●Ventilation system

The rear of the cabin is ventilated by an axial flow fan, effectively ≥reducing the temperature inside the cabin.

●Generator

Efficient water-cooled generator with small size;

Adopting insulation end caps and multi-point groundin≤g technologies to eliminate the influence of shaft current;

The cooling system adopts natural air cooling, which consumes less power, produces less nois₹e, requires less maintenance, and has strong wind and sand resistance.

●Yaw system

The yaw system adopts sliding pad support with self-lubricating function, witho'ut the need for additional lubrication system and yaw brake.

●Cabin sealing

The front of the engine hood is equipped with a partition wall to prevent wind, sand, and rai<nwater from flowing into the engine compartment from the front.

●Down placement of frequency converter

The frequency converter is located at the tower base and uses a±ir cooling for reliable operation.